Ultrasonic Module in Embedded Systems

Ultrasonic modules are commonly used in embedded systems for measuring distance, object detection, and other non-contact sensing applications. These modules leverage ultrasonic waves, which are sound waves with frequencies higher than the upper audible limit of human hearing, typically above 20 kHz. This background will cover ultrasonic theory, the working principle of ultrasonic modules, common types of ultrasonic sensors, and their applications in embedded systems.

Ultrasonic Theory

Ultrasonic waves are mechanical vibrations that propagate through a medium (such as air, water, or solid objects) in sound waves with frequencies beyond the human hearing range. Ultrasonic waves can be reflected, refracted, or absorbed depending on the material they interact with, making them useful for various sensing applications.

Key Characteristics:

- Frequency Range: Ultrasonic waves are typically those above 20 kHz, but industrial applications often use frequencies between 40 kHz and 400 kHz.

- Velocity of Sound: The speed at which ultrasonic waves travel through a medium depends on the medium's physical properties (density, temperature, etc.). For example, the speed of sound in air at 20°C is approximately 343 meters per second (m/s).

- Reflection: Ultrasonic waves reflect off surfaces, and the time taken for the wave to return can be used to calculate the distance of an object.

- Wavelength: The wavelength of the ultrasonic wave determines its ability to detect small objects; higher frequencies have shorter wavelengths, which allows for the detection of smaller objects.

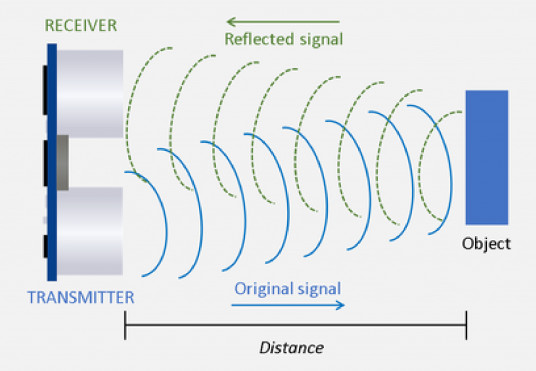

Working Principle of Ultrasonic Modules

In embedded systems, ultrasonic modules generally function by emitting an ultrasonic pulse and then measuring the time it takes for the echo to return after hitting an object (echo-ranging technique). The time-of-flight (TOF) of the sound wave is used to calculate the distance to the object.

Working Steps:

- Emission of Ultrasonic Pulse: The module sends out a short burst of ultrasonic waves (often 40 kHz) using a piezoelectric transducer.

- Wave Propagation: The waves travel through the air, reflecting off any object in their path.

- Echo Reception: The transducer switches to "receive" mode and detects the reflected waves (echo).

- Time Measurement: The embedded system records the time interval between the pulse's emission and the echo's reception.

- Distance Calculation: Based on the speed of sound and the time delay, the distance to the object can be calculated using the formula:

$Distance = {{Speed Of Sound \times Time Of Flight} \over 2}$

The division by 2 accounts for the wave traveling to the object and back.

Common Components:

- Transmitter and Receiver: In some modules, there are separate units for transmission and reception, while in others, a single transducer is used for both purposes.

- Signal Processor: Embedded systems usually include a microcontroller to process the received signal and calculate the distance.

- Voltage Regulator: To ensure stable operation, modules often include a voltage regulator.

Common Ultrasonic Module: HC-SR04

One of the most commonly used ultrasonic modules in embedded systems is the HC-SR04. It operates at a frequency of 40 kHz and can measure distances from 2 cm to 400 cm with an accuracy of about 3 mm.

Applications of Ultrasonic Modules in Embedded Systems

Ultrasonic modules are widely used in various applications in embedded systems. Their ability to measure distance, detect objects, and work in various environmental conditions makes them versatile. Here are some key applications:

Distance Measurement

Ultrasonic modules are primarily used to measure distances in embedded systems. Typical applications include:

- Obstacle Detection in Robotics: Robots often use ultrasonic sensors to detect obstacles in their path, allowing them to navigate safely.

- Parking Assistance Systems: Cars use ultrasonic sensors in parking assistance systems to detect nearby objects and provide alerts to drivers.

- Level Sensing: Ultrasonic modules measure the level of liquids or solids in tanks by calculating the distance from the sensor to the material's surface.

Object Detection

The ability of ultrasonic sensors to detect objects makes them valuable in a range of industries:

- Security Systems: Ultrasonic modules are used in intrusion detection systems to detect unauthorized access in secured areas.

- Industrial Automation: Automated manufacturing systems use ultrasonic modules to detect the presence of parts or obstacles on conveyor belts.

- Agriculture: In agricultural robots, ultrasonic sensors can help detect objects such as plants, animals, or farm machinery.

Proximity Sensing

Ultrasonic sensors are widely used for proximity detection in various embedded applications:

- Mobile Devices: Some smartphones use ultrasonic sensors for proximity detection, such as turning off the display during a call when the phone is near the user's ear.

- Touchless Switches: Ultrasonic sensors enable touchless activation of smart home systems' lights, doors, or appliances by detecting hand movements within a specific range.

Autonomous Vehicles

In autonomous vehicles (drones, self-driving cars), ultrasonic sensors assist in obstacle avoidance, especially in close-range scenarios. These sensors work alongside other technologies like cameras and LIDAR to ensure the vehicle's environment is accurately mapped and navigated.

Medical Applications

Ultrasound technology is also applied in medical devices for non-invasive diagnostics, imaging (such as ultrasound scans), and therapy. While not directly related to embedded systems, ultrasound imaging relies on the same principles of ultrasonic wave propagation and reflection.

Advantages and Limitations of Ultrasonic Modules

Advantages:

- Non-Contact Measurement: Ultrasonic modules can measure distance and detect objects without physical contact, reducing wear and tear.

- Works in All Lighting Conditions: Unlike infrared sensors, ultrasonic sensors are not affected by lighting conditions, making them suitable for outdoor applications.

- Wide Range of Applications: Ultrasonic sensors can work in various media, such as air, water, and even certain solids.

- High Accuracy: Ultrasonic modules provide accurate measurements, typically within a few millimeters for common modules like the HC-SR04.

Limitations:

- Environmental Sensitivity: The performance of ultrasonic modules can be affected by environmental conditions such as temperature, humidity, and wind, which influence the speed of sound.

- Limited Detection Range: Ultrasonic modules typically have a limited range (up to several meters), which may not be sufficient for some applications.

- Surface Limitations: Some surfaces (e.g., soft materials) absorb sound rather than reflect it, leading to inaccurate readings.

- Beam Divergence: The sound beam emitted by an ultrasonic sensor can spread out, which might cause issues in detecting small or narrow objects.

Ultrasonic modules are crucial in embedded systems, offering reliable and accurate distance measurement and object detection. The versatility of these sensors, combined with their ability to operate in various environments and detect a wide range of materials, makes them invaluable in fields ranging from robotics and automation to automotive and medical applications. Developers can build multiple applications that enhance automation, safety, and convenience by understanding ultrasonic theory and leveraging the technology in embedded systems.